First Article Inspection Report (FAIR)

EMPB is an abbreviation for Initial Sample Inspection Report

Initial sample inspection report

All test results of the initial sample are documented in the initial sample test report (EMPB).

Definition: The initial sample inspection report, or EMPB for short, is a central factor in the sampling process for the acceptance of production parts and products. One could also say that the EMPB is a kind of criteria catalogue for the production and acceptance of products; all test results on the initial sample are documented here.

Before a part or product can go into series production, the first parts produced under series conditions are presented to the customer for testing. These first products are called Initial Sample, the examination by the client is called Initial sample inspection. For the customer, the initial sample inspection is the first and last opportunity to carry out a quality control of the ordered goods before they go into serial production.

Designations and allocation

- German designation:

First Article Inspection Report (FAIR) - English designation:

First Article Inspection Report (FAIR) - Standard set of norms and rules:

VDA Volume 2 - Assuring the quality of deliveries

Purpose of an EMPB

With the initial sample inspection report, the supplier (subcontractor) can prove to the customer (manufacturer) that the delivered products meet the customer's specifications and quality requirements. In the EMPB, the customer informs the supplier of the target and the determined actual values of the product or production part. In addition, the initial sample inspection report summarises and documents all important information about the product, such as product requirements, quality and necessary tests.

Function of EMPBs

Thus, the initial sample inspection report serves to document the results of the initial samples according to the client's specifications before the series run. The informative value and complexity of initial sample inspection reports can vary.

Occasion of EMPBs

The reason for preparing an initial sample inspection report can be the following: New design, redesign or to check the manufacturer's quality. Depending on the agreement, initial sample inspection reports are created by both the supplier and the manufacturer (recipient).

In the event of a new production of the product concerned, this shall be carried out under the same conditions and shall be based on the initial sample.

Retention periods for initial sample inspection reports

The retention of initial sample inspection reports is governed by §257 para. 1 HGB and § 147 AO. As a rule, however, an archiving period of 10 years applies to initial sample inspection reports.

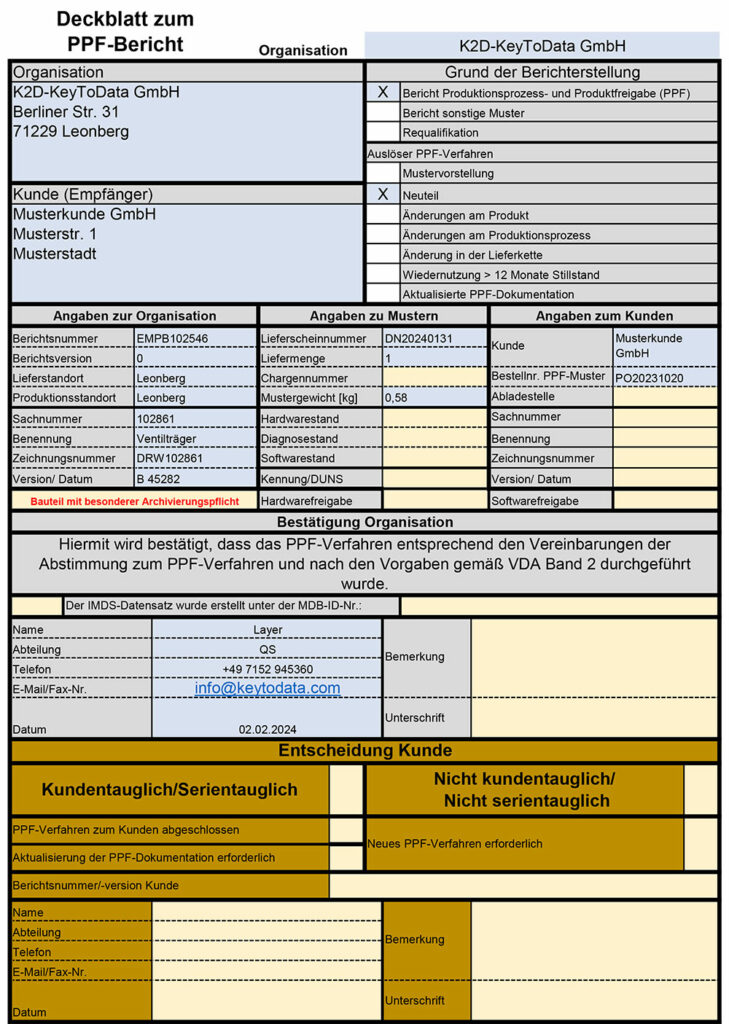

EMPB cover sheet according to EMPB

Template and example for an EMPB cover sheet according to VDA

Related articles:

What is an initial sample?

What is PPAP?

What is APQP?

PPAP Excel-Template

Free of charge | English | Complete

50% time saving in Inspection Report generation. Publish Inspection Reports according to VDA, PPAP, AS9102 or custom templates.

Free Trial

With the Ideagen Quality Control software (formerly InspectionXpert), you can create precise EMPB in no time at all.

- Free training & support

- Software with full range of functions

Software distribution for over 25 years

KeyToData has been distributing highly specialised software for companies in the manufacturing industry since 1995.

Support without waiting on hold

We do not leave you alone during the implementation of new software. Even during ongoing software operation, we are always available to answer your questions.

Selection of our software solutions for companies

FAQ: Initial sample inspection report (EMPB)

○ When initial sample inspection report?

If a part or product is to be produced in series, the initial sample inspection report (EMPB) specifies what is to be observed during production before production starts. Target and actual values of the part or product to be produced are specified in the EMPB.

The EMPB is used for quality assurance and is created within the scope of the initial sample inspection. Reasons why an initial sample inspection report is prepared are, for example:

- Start of serial production

- Redesign of a product

- Quality inspection

○ What does an EMPB contain?

The initial sample test report documents the results of the test on the "initial sample", such as:

- Dimensions

- Materials

- Tools

- special properties

- ...

All relevant target and actual values of a part/product are documented in detail in the initial sample inspection report, so that in the event of faulty production, errors can be quickly detected and rectified - ideally before the start of serial production.

○ Who prepares the EMPB?

As a rule, initial sample inspection reports are created by suppliers or manufacturers. The initial sample test report serves the supplier as proof to the customer that the delivered products meet the quality requirements defined in the EMPB. The customer can use the initial sample inspection report to provide the manufacturer or supplier with target and actual values for a part or product to be produced.