PPAP

Production Part Approval Process

Our content sections

Glossary article

PPAP Excel-Template

Free of charge | English | Complete

Definition

The Production Part Approval process is a framework of requirements for series parts used in the automotive environment. PPAP is used to prove the quality of suppliers and their manufacturing processes.

The purpose of PPAP is for suppliers to demonstrate that they have understood the customer's design and in series production, to produce products that consistently meet all requirements and specifications, while maintaining the production rate.

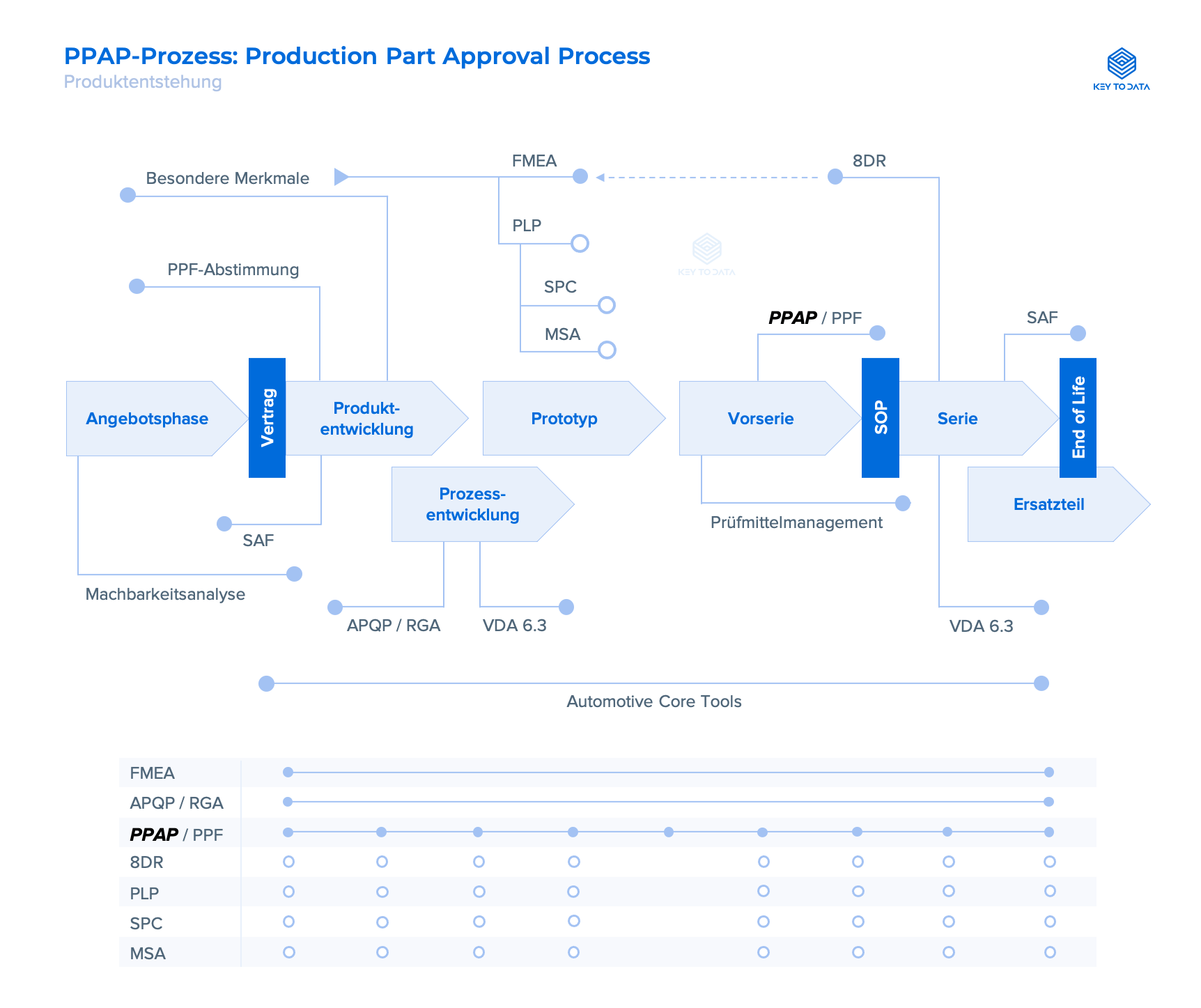

Graph: Product creation

The chart providing an overview of the product creation can be downloaded for free as a PDF by clicking on the button. The download will open in a new tab.

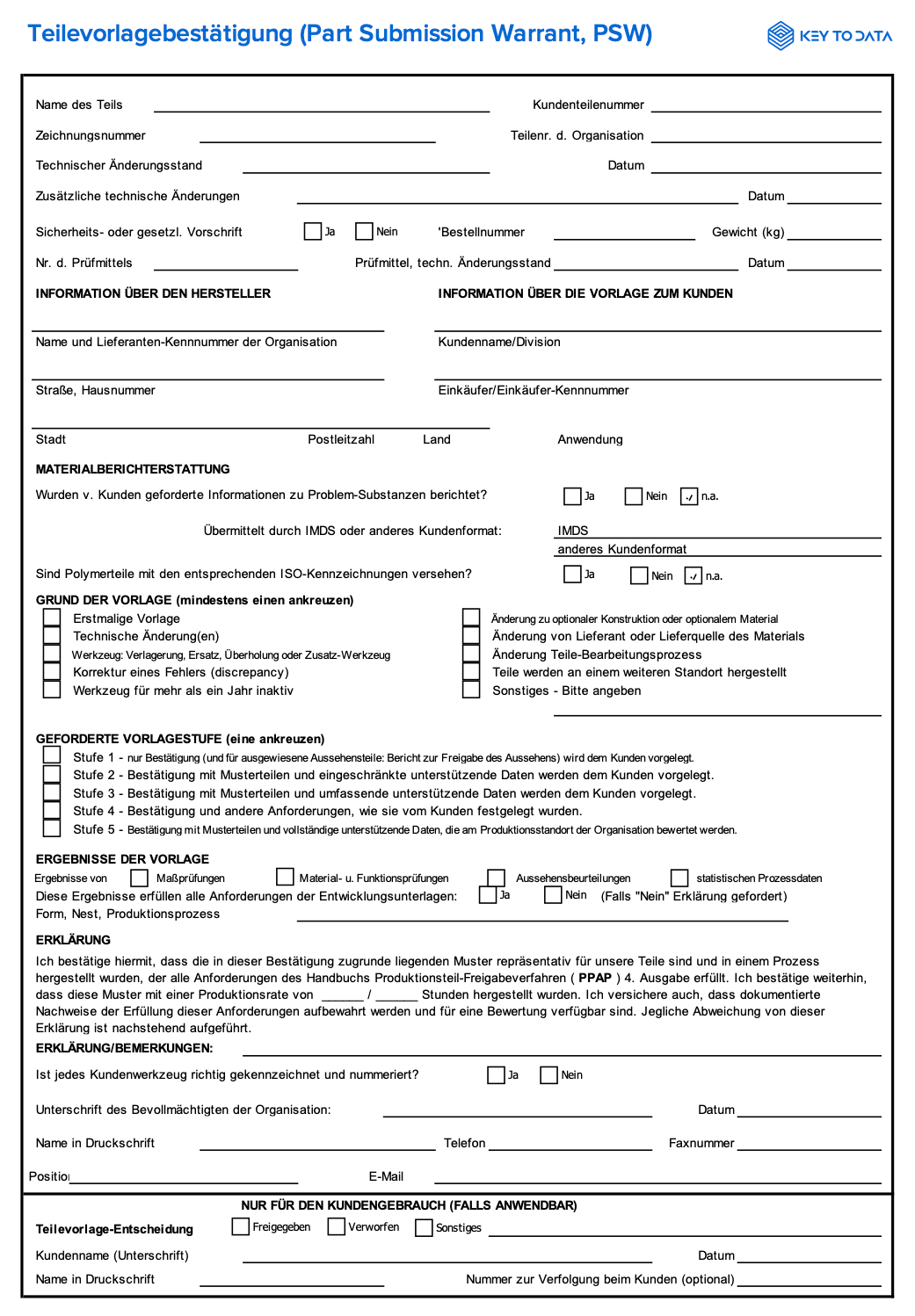

Part Submission Warrant (PSW)

The Part Submission Warrant (PSW) is an essential part of the PPAP process and must always be sent to the customer. According to the AIAG PPAP manual, all elements should be completed.

Dividing the PSW into 5 levels

- Level 1: Only the Part Submission Warrant (PSW).

- Level 2: PSW with product samples and limited supporting data.

- Level 3: PSW with product samples and complete supporting data.

- Level 4: PSW and other requirements as defined by the customer.

- Level 5: PSW with product samples and complete supporting data available for review at the supplier's manufacturing location.

PSW template

A Part Submission PSW template is available for download from our free "PPAP Excel Template" integrated.

18 PPAP Requirements

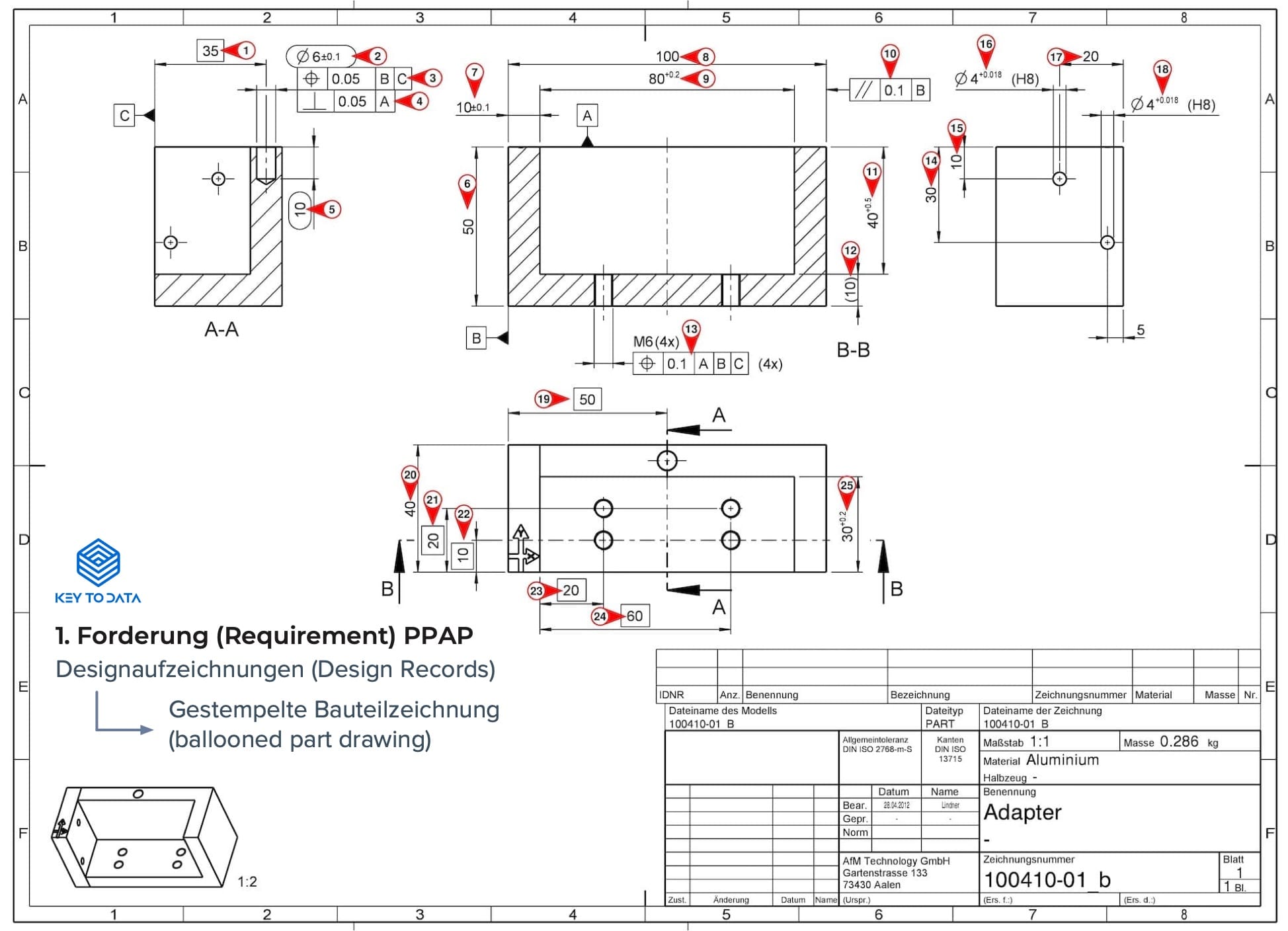

1. Design Records

A part drawing of the component, usually provided by the customer. Each feature of the part drawing must be ballooned to match the inspection results. This needs to include print notes, standard tolerance notes and specifications, as well as any other information relevant to the design of the part.

Example: Below is an example of a ballooned part drawing.

Why a copy of the part drawing belongs in your PPAP?

It shows the customer that you have a copy of the part drawing and makes sure that you are both discussing the same part.

Video: Creating a dimensional report for PPAP

In the following video we show you how to create a dimensional report for PPAP using the FAI software InspectionXpert:

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information2. Engineering Change Documents

A document showing the detailed description of a change, which is usually called a "technical change note". This document is only required when a change has been made.

3. Customer Engineering Approval

This approval is usually the engineering trial with sample production parts performed by the customer. A "temporary deviation" is often required to send parts to the customer before the PPAP is complete. Your customer may require other additional engineering approvals.

4. Design FMEA

Design Failure Mode and Effect Analysis (DFMEA) is an application of the Failure Mode and Effects Analysis (FMEA) that is specific to the design stage. The DFMEA allows the design team to document what they predict about a product's potential failures before completing a design and use this information to mitigate the causes of failure.

5. Process Flow Diagrams

The Process Flow Diagram shows all the steps required in the manufacturing of the part. It should include all of the main steps in the processing of the part including incoming components, measuring, and inspection. The Process Flow Diagram should match the control plan and the Process Failure Mode and Effects Analysis (PFMEA) and also includes the flow of non-conforming materials and parts.

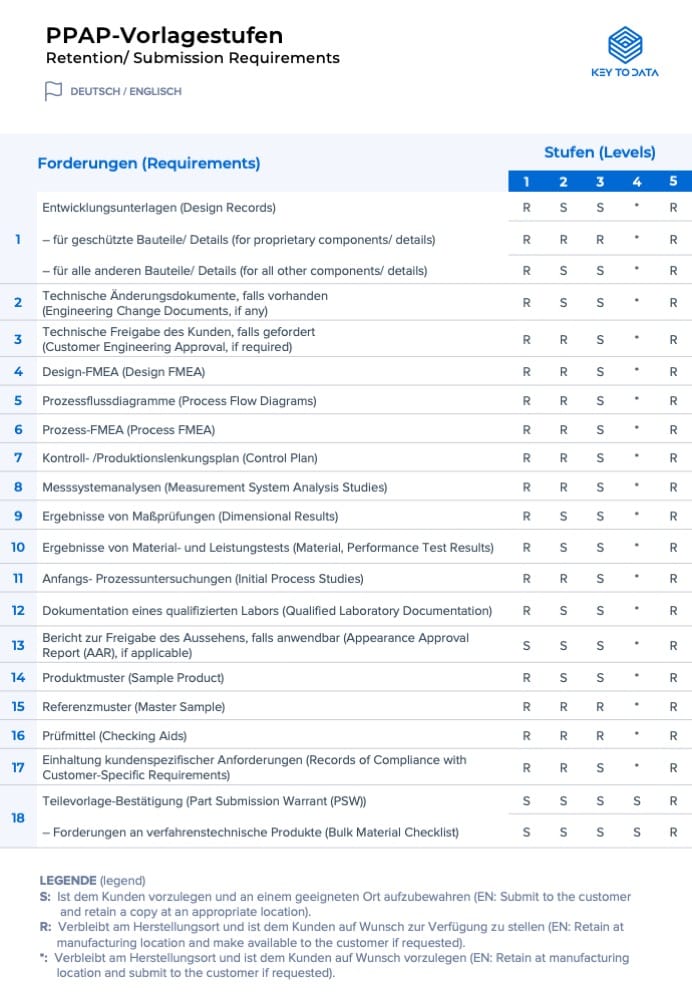

Overview table of the PPAP Process Requirements: German and English

Requirements 1 to 18 and respective the Submission Levels 1 to 5.

Legend: S | R | *

- S: Submit to the customer and retain a copy at an appropriate location.

- R: Retain at manufacturing location and make available to the customer if requested.

- *: Retain at manufacturing location and submit to the customer if requested.

Overview of the PPAP Submission Requirements

(PPAP Submission Levels Template)

TABLE: GERMAN - ENGLISH

PDF-Download

- Level

- Level

- Level

- Level

- Level

| Requirement (Forderung / DE) | Level | Level | Level | Level | Level |

| Requirement (Forderung / DE) | 1 Stufe (DE) | 2 Stufe (DE) | 3 Stufe (DE) | 4 Stufe (DE) | 5 Stufe (DE) |

| 1.  Development documents (Design Records) | R | S | S | * | R |

| - for proprietary components/ details (for proprietary components/ details) | R | R | R | * | R |

| - für alle anderen Bauteile/ Details (for all other components/ details) | R | S | S | * | R |

| 2.  Technical change documents, if available (Engineering Change Documents, if any) | R | S | S | * | R |

| 3.  Technical approval of the customer, if required (Customer Engineering Approval, if required) | R | R | S | * | R |

| 4.  Design FMEA (Design FMEA) | R | R | S | * | R |

| 5.  Process flow diagrams (Process Flow Diagrams) | R | R | S | * | R |

| 6.  Process FMEA (Process FMEA) | R | R | S | * | R |

| 7.  Control/production control plan (Control Plan) | R | R | S | * | R |

| 8.  Measurement system analyses (Measurement System Analysis Studies) | R | R | S | * | R |

| 9.  Results of dimensional checks (Dimensional Results) | R | S | S | * | R |

| 10.  Results of material and performance tests (Material, Performance Test Results) | R | S | S | * | R |

| 11.  Initial process investigations (Initial Process Studies) | R | R | S | * | R |

| 12.  Documentation of a qualified laboratory (Qualified Laboratory Documentation) | R | S | S | * | R |

| 13.  Appearance release report, if applicable (Appearance Approval Report (AAR), if applicable) | S | S | S | * | R |

| 14.  Product samples (Sample Product) | R | S | S | * | R |

| 15.  Reference sample (Master Sample) | R | R | R | * | R |

| 16.  Test equipment (Checking Aids) | R | R | R | * | R |

| 17.  Compliance with customer-specific requirements (Records of Compliance with Customer-Specific Requirements) | R | R | S | * | R |

| 18.  Parts template confirmation (Part Submission Warrant (PSW)) | S | S | S | S | S |

| - Requirements for process engineering products (Bulk Material Checklist) | S | S | S | S | S |

6. Process FMEA

Process Failure Mode and Effects Analysis (PFMEA) evaluates each step in the production process to indicate what could go wrong during the fabrication and assembly of each part.

7. Control Plan

The Control Plan mirrors the PFMEA (Process Failure Mode and Effects Analysis) and provides more details on how potential issues are checked in the incoming inspection, assembly process, or during the inspection of the finished part.

8. Measurement System Analysis Studies

The Measurement Systems Analysis is a study itself and will conform to the customer's relevant ISO or TS standard. Typically it includes the Gauge R&R (Gauge Repeatability and Reproducibility) for the critical characteristics and a confirmation that gauges used to measure these characteristics are calibrated.

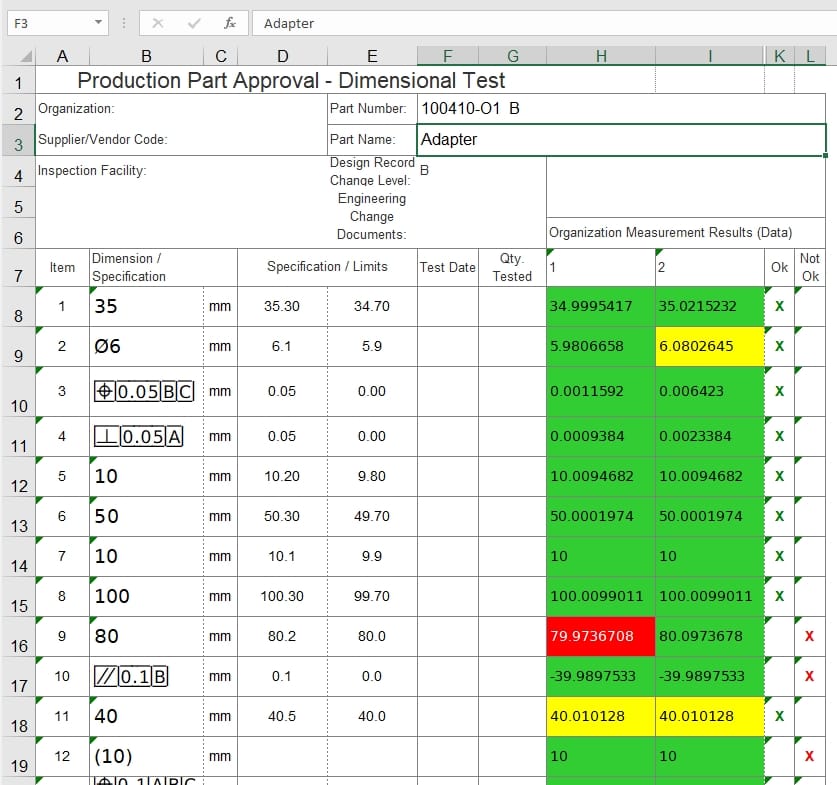

9. Dimensional Results

A list of all test characteristics stamped on the test mark including the measurement results. The list contains the product property, specification, measurement results and the evaluation showing whether the requirement is "fulfilled" or "not fulfilled" ("Ok" or "Not Ok"). Normally, at least 6 samples per product are tested.

Below is an example of a PPAP dimensional inspection results report. Learn more about creating a PPAP dimensional measurement report and how to import measurement results from CMMs into your dimensional inspection results.

Image: PPAP measurement results (Dimensional Report)

10. Material, Performance Test Results

A summary of all tests that have been performed on the part. The summary should document any pass or fail inspection results. It should be signed off by the customer and the supplier to show that all required tests have been done and any additional data for tests have been submitted.

11. Initial Process Studies

Generally, this includes SPC (Statistical Process Control) charts for critical characteristics. These studies demonstrate that the critical processes are stable and are ready to begin the process validation builds.

12. Qualified Laboratory Documentation

Includes all of the industry certifications for any lab that was involved in completing validation testing.

13. Appearance Approval Report (AAR)

The Appearance Approval Report verifies that the customer has inspected the final product and it meets all the required appearance specifications for the design. The report includes color, textures as well as fit (gaps between parts), etc.

14. Sample Product

A picture of the production parts is included in the PPAP documentation along with the location where the parts are stored.

15. Master Sample

A sample part that is signed off by the customer and supplier. The master part is normally used to train operators on subjective inspections such as visual or for noise.

16. Checking Aids

Checking aids are used by production and are a detailed list of all the tools used to inspect test or measure parts during the assembly process. This aid will list the part, describe the tool and have the calibration schedule for the tool.

17. Records of Compliance with Customer-Specific Requirements

This section of the PPAP documentation lists requirements of specific industries and the individual requirements of the customer.

18. Part Submission Warrant (PSW)

The Part Submission Warrant is a summary of the entire PPAP submission and specifies:

- Drawing numbers and revisions

- Information about the part

- Test results

- Material declarations numbers

- Any deviations from earlier elements.

Difference between PPAP and APQP

PPAP (Production Part Approval Process) is a component of APQP (Advanced Product Quality Planning).

How does PPAP affect APQP?

If the PPAP results don't meet customer expectations, that usually means the APQP process isn't working properly. The test for both APQP and PPAP is a production trial run. If the finished trial product includes defective parts, the manufacturer has to go over the supply chain and find out where PPAP or APQP went wrong.

Related articles:

What is APQP (Advanced Product Quality Planning)? (DE)

What is the difference between PPAP and PPF? (DE)

What is PPF? (DE)

What is a First Sample Test Report? (DE)

PPAP Excel-Template

Free of charge | English | Complete

50% time saving in Inspection Report generation. Publish Inspection Reports according to VDA, PPAP, AS9102 or custom templates.

Free access for 14 days

Inspection reports in minutes, not hours

- Free training & support

- Full functionality