PPF vs. PPAP

Production process and product release

Difference between PPF and PPAP

How the PPF procedure also, is PPAP (Production Part Approval Process) a procedure for ensuring quality, but the PPAP procedure is based on the American working group for supplier quality requirements (AIAG = Automotive Industry Action Group). Whereas PPF is based on the German automotive industry (VDA Volume 2).

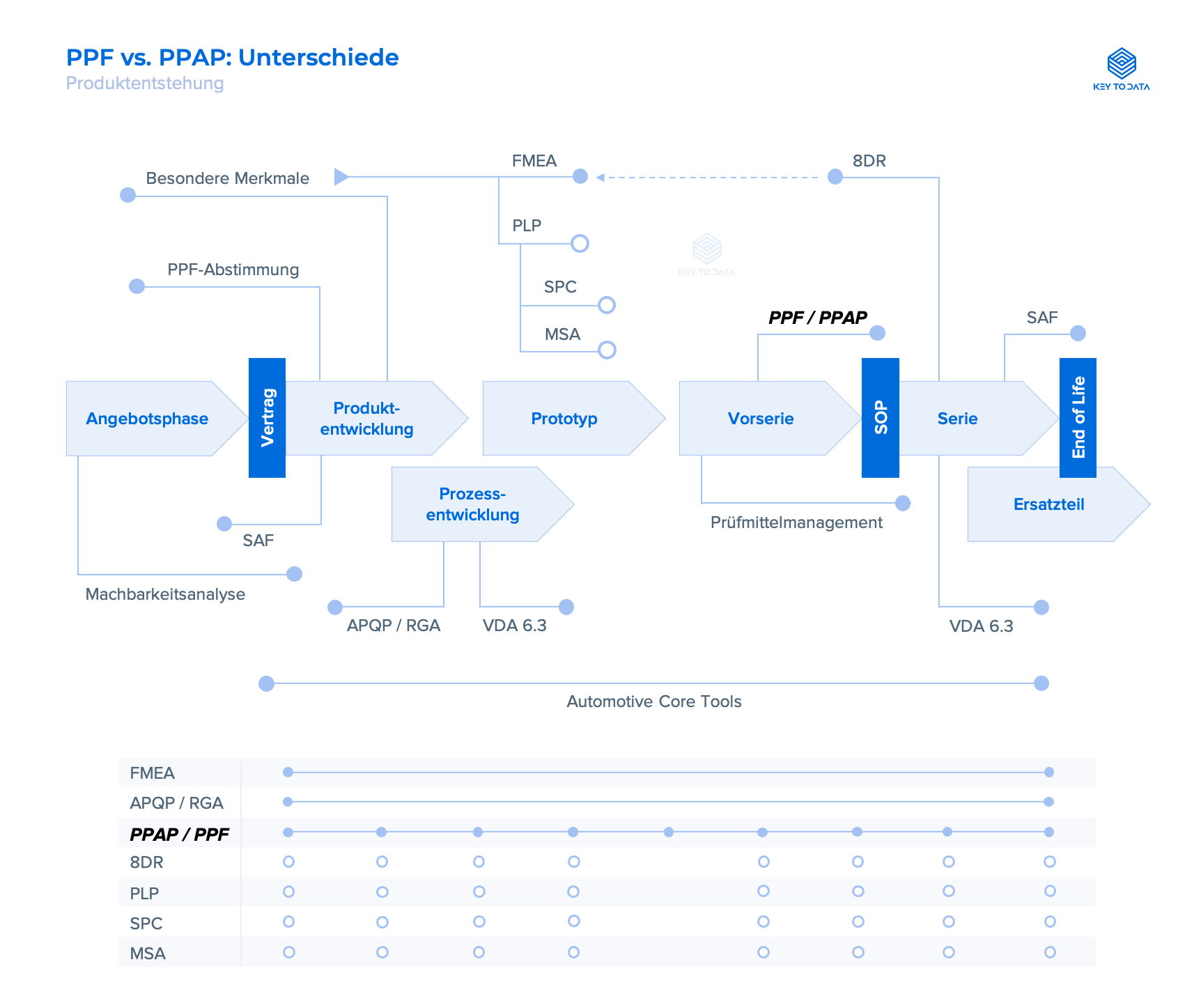

Graph: Product creation

Table: Comparison PPF vs. PPAP

What are the differences or similarities between PPF and PPAP? The following table shows which stages (levels) of the PPAP process correspond to PPF and for which PPF contents there is no equivalent in PPAP (✘).

PPF contents | PPAP | |

| Cover sheet for the PPF report | 18 | |

| 1 | Test results for product release: (e.g. geometry, dimension, function, material (e.g. strength, physical properties), haptics, acoustics, odour, appearance, surface, reliability, EMC/ESD testing, electrical safety, etc.). | 9, 10, 13, 17 |

| 2 | Samples (number or delivery quantity by agreement) | 14 |

| 3 | Technical specifications (e.g. customer drawings, CAD data, specifications, approved design changes, short-circuit resistance, voltage protection, functional safety (FUSI), etc.). | 1, 2 |

| 4 | FMEA (product and process) | 4 |

| 5 | Design and development releases of the supplier with development responsibility according to agreement | ✘ |

| 6 | Proof of compliance with legal requirements, if agreed with the customer (e.g. environment, safety, recycling, country-specific certificates). | 17 |

| 7 | Material data sheet per IMDS | 10 |

| 8 | Software test report, process conformity | ✘ |

| 9 | FMEA process | 6 |

| 10 | Process flow diagram (manufacturing and test steps) | 5 |

| 11 | Production Control Plan | 7 |

| 12 | Proof of process capability | 11 |

| 13 | Proof of protection of special features | 17 |

| 14 | Test substance list (product-specific) | 16 |

| 15 | Test equipment capability study, where appropriate (result) | 11, 16 |

| 16 | Tool overview (with number of pieces / number of nests and information on the tool concept) | ✘ |

| 17 | Proof of achievement of the agreed capacity (process validation) | ✘ |

| 18 | Written self-assessment of the criteria according to the matrix Assessment of readiness for series production for product and process | ✘ |

| 19 | Parts history | 2 |

| 20 | Proof of suitability of the means of transport used | ✘ |

| 21 | Overview of the individual parts of the supply chain (vendor parts, set parts and house parts) with decision PPF | ✘ |

| 22 | Release of coating system according to customer requirements | ✘ |

| PPAP 12 and 15 are not included in the PPF. | ||

Documentation of the procedures

When the parts delivered for inspection are handed over, documents must be handed over that contain all the important information, tests and requirements. At the AIAG, one speaks of PSW (Part Submission Warrant) and at the VDA of EMPB (Initial sample inspection report).

VDA Volume 2: 2020 | 6th edition

In the 6th edition of VDA Volume 2, the template stages are dropped in order to better meet the requirements and individual wishes of the customer. Another innovation from VDA Volume 2 is the approximation of the PPF procedure to the PPAP procedure of the AIAG. In our Blog entry we describe the innovations and highlights of the 6th edition.

Related articles:

How does the PPF process work?

What is a First Sample Test Report? (DE)

What is PPAP?

What is APQP?

What is a PSW?

PPAP Excel-Template

Free of charge | English | Complete

50% time saving in Inspection Report generation. Publish Inspection Reports according to VDA, PPAP, AS9102 or custom templates.

Free access for 14 days

Inspection reports in minutes, not hours

- Free training & support

- Full functionality